Instructions for Use

Home / FrogLube Products / Instructions

Complete and detailed Firearm Cleaning and Lubrication Guide

FROGLUBE’S ‘GUN CARE 101’ PDF [HERE] FROGLUBE’S ‘RIFLE AND BARREL MAINTENANCE' [HERE]

FROGLUBE’S 'ULTRASONIC CLEANER USE' [HERE]

Proper preparation delivers best results

-

Your new weapon is likely factory-treated with a lubricant or protectant of a petrochemical substance or you may have used a petrochemical or other substances on your weapon.

-

For your first application; for best performance, it is preferred to remove any petroleum fouling or residue from your weapon using FrogLube Solvent™ prior to applying FrogLube.

-

It’s best to clean ALL surfaces with FrogLube cleaning products – FrogLube cleaners do not leave a residue.

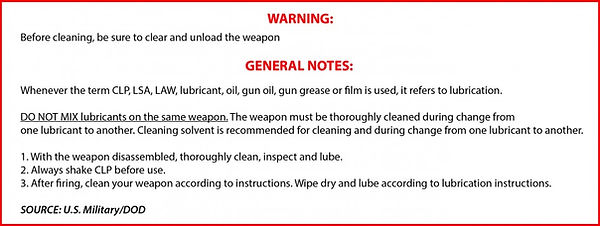

NOTE: Avoid mixing FrogLube products with petroleum-based cleaners and lubricants. This may cause unforeseen or unintended reactions during use or storage.

Normal Care and Use: 2 steps

Step 1: Firearm Cleaning:

Use FrogLube Cleaners; Either FrogLube Solvent™ or Super Degreaser™

• Remove ‘heavy’ grease or stubborn fouling with a swab, brush and/or patch.

• Flush fouling from internals using generous amount of cleaner by spray or immersion.

• Cleaners are fully activated after 1-3 min.

• Agitate/scrub surface with brush, swab, towel or cleaning tool. You may notice a slight foaming on the surface.

• Wipe off fouling and moisture with a towel, patches or compressed air to remove all moisture.

Ultrasonic cleaner: Solvent is non-flammable and may be used in conjunction with a heated ultrasonic cleaning tank. Check with manufacturers instructions for compatibility and user instructions. Test cleaning performance at 3 min. intervals.

The surface should now be clean, dry and ready for lube/protectant application.

For Heavy Fouling or Stubborn Fouling use FrogLube Super Degreaser concentrate**

Mix: For Heavy fouling use at full strength or 1:1, Medium fouling 5:1, Light fouling 10:1

Step 2: Firearm Lubrication and Preservation

For best results, apply to a clean and dry surface.

FrogLube will absorb into metal. (heat will quicken the rate of absorption)

Apply drops or wipe on the surface as needed. Scrub if dirty, wipe off excess. The lube will remove carbon and rust.

Lubricate action per manufacturers instruction. Do not over lube the action. FrogLube will work dry or wet. Note: In hot/dusty or extreme cold conditions, excess lube should be removed.

Additional Care Instructions:

Storage

Firearms should be thoroughly cleaned and inspected (Steps 1 and 2) prior to placing in storage.

At a set interval (90 days or what works best for your situation), the firearm should be inspected.

IMPORTANT: When the firearm is withdrawn from storage, it should be thoroughly cleaned and lubricated (repeat as in Steps 1 and 2), function checked and live fire tested to self-certify it is ready for duty. If your firearms manual allows, and you live in a harsh or moist climate, you a light coat may be applied for additional protection.

Harsh Exposures.

For more demanding conditions, such as salt water, humidity or extended storage durations, you may apply a light coat of FrogLube on parts and exposed surfaces. Do not over lube the action to prevent sluggish movement.

Deep Cleaning and Extra Care

Froglube recommends cleaning and inspecting after every use.

• If you notice a ‘build-up’ or increased friction during cycling, it may be due to a lack of cleaning, built up fouling and you may sustain sluggish performance. Do a field strip and apply a generous amount of FrogLube Solvent or Super Degreaser to flush out contamination from all parts and spaces. You will find amazing cleaning results and this should normally return the firearm to peak operating performance.

• After long-term storage, you should do a thorough field strip, clean and inspect.

• In the event the firearm is over lubricated, do a thorough cleaning with FrogLube Solvent or Super Degreaser; it will remove excess lubricant trapped in the action and inside the firearm spaces.

Bore: FrogLube Cleaners clean copper and lead

Follow manufacturers procedures

for bore “break-in”

-

Scrub internal bore surface with a generous amount of solvent using a chamber and bore brush along with wet patches, followed by dry patches until clean and dry.

-

Repeat this step until patches reveal little to no fouling. Vigorous friction applied to surfaces increases cleaning performance.

-

Run a saturated FrogLube lube patch to ‘season’ the barrel surface. Allow to soak for 5 min, then run dry patches until excess is removed.

FrogLube's Bio-Based Cleaners & Lubricants are the Future of Gun Care and Maintenance.

NOTE: All of FrogLube’s products are bio-based, non-hazardous and environmentally friendly. However, for important health and safety information, please refer to the Safety Data Sheet (SDS) for our products. For additional product information or application advice, please contact FrogLube Products at 1-855-FROGLUBE or write us directly at contact@froglube.com

*If you have any concerns about using FrogLube products, try in a non-descript area of your firearm to confirm compatibility.

** FrogLube Super Degreaser is recommended when switching from petroleum-based firearms care products.